Step Ladder Safety: Are You Standing Too High?

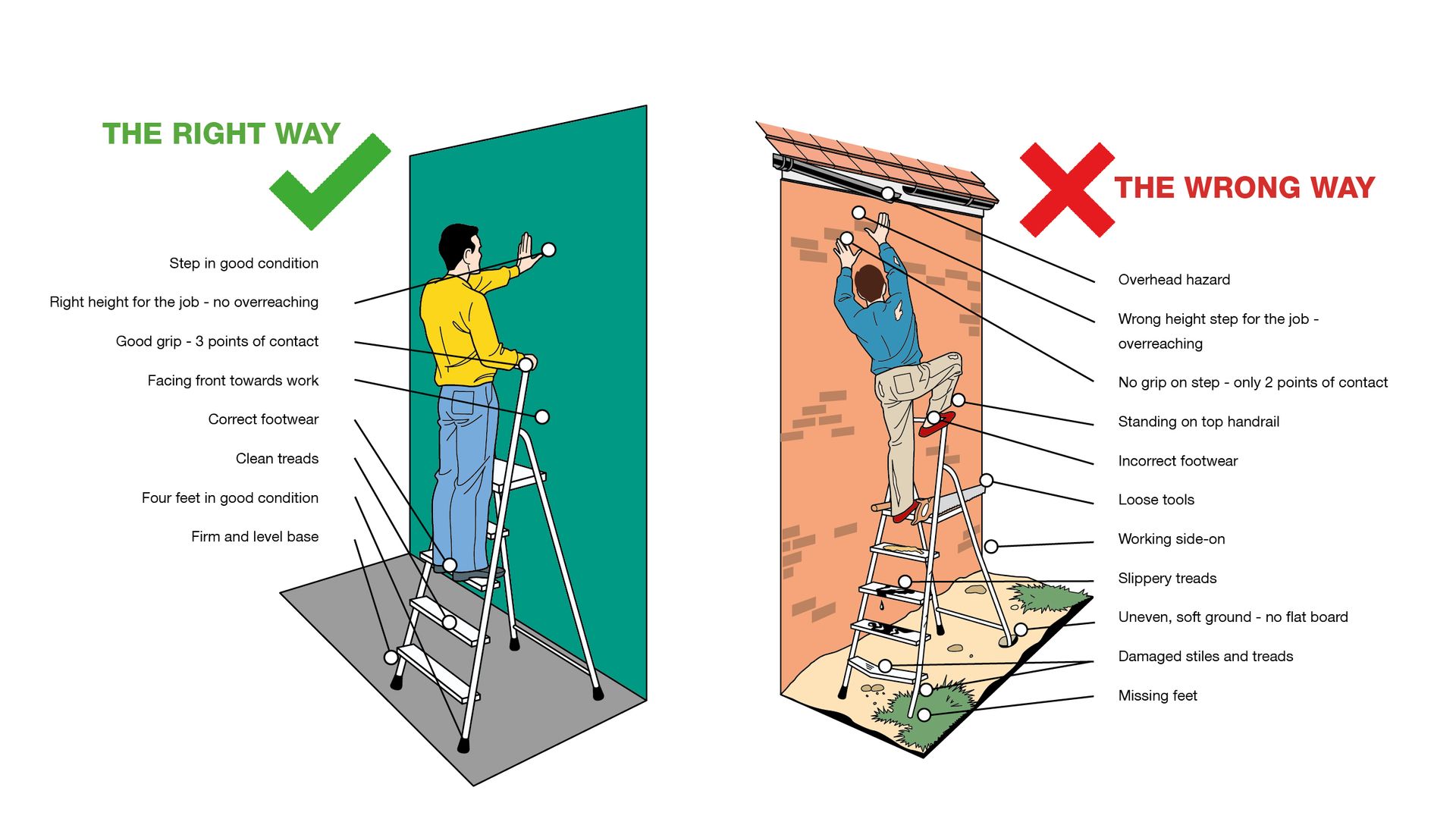

When it comes to working at height, step ladders are one of the most commonly used access tools across construction, maintenance, facilities management, and beyond. But many users are unaware of one crucial detail that could compromise their safety: which tread you're allowed to stand on.

Surprised? You’re not alone.

The Top Tread Trap: What You Need to Know

According to The Ladder Association’s Code of Practice, users should never stand on the top three treads of a step ladder unless it has a built-in platform and knee rail (also known as a safety bar).

Standing too high not only puts the user at risk of losing balance or overreaching but also goes against industry-recognised safe working practices. It limits stability, reduces the user’s centre of gravity, and increases the chance of serious injury from a fall.

So, How High Can You Go?

Here’s a general rule of thumb based on Ladder Association guidelines:

- Without a platform and safety bar:

You should not stand above the third tread from the top. - With a platform and safety bar (like

MagnaStep Platform or

Widestep models):

You can safely stand on the platform - as it provides the required support and guardrail for working at height.

Remember: The top tread of a step ladder or the highest part is never a standing surface - it’s there for structural integrity, not your boots!

Safe Step Ladder Options from Lyte

At Lyte Ladders, safety is at the heart of everything we build. That’s why we design our step ladders to not only meet but exceed the EN131 Professional standard.

Here’s how our MagnaStep range supports safer use of step ladders:

- Magnetic Tool Tray: Reduces dropped-object incidents by keeping tools and fixing securely within reach

- Greater Tread Pitch (295mm): Increases working height without increasing step count, reducing strain on users

- Repairable Designs – Extend lifespan and ensure continued safety through maintenance

- Green Aluminium Treads – Lower-carbon, durable materials

- Made in the UK – Ensures consistent manufacturing and quality control

- Platform Step Ladders – Provide a large, flat working surface with knee bar protection

- Widestep Ladders – Offer extra-wide platforms and 360° working access due to the built-in safety bar and handrails.

Final Tip: Training Matters

We always recommend that step ladder users complete a certified training course, like those offered by The Ladder Association, to ensure they’re aware of how to use ladders safely, check for faults, and understand best practice.

For more information, visit:

🔗

www.ladderassociation.org.uk

Need Advice on Choosing the Right Step Ladder?

Speak to our team about selecting the safest, most appropriate solution for your business:

t. 01792 796 666