Health & Safety Hub

Working-at-Height Safety, Standards & Tools

Your essential resource centre for ladder compliance, inspection tools, product safety, and sustainability in working at height.

Compliance & Inspection Resources

We know that Health & Safety professionals need more than just great ladders to ensure the safety of your teams. You also need the proof, tools and documentation that stand up to audits. Below are free resources to help you with compliance, inspection, tendering and equipment specification:

Our Certification

Safety Focussed Articles

Explore expert blog posts to help you make better, safer decisions when choosing and using working‑at‑height equipment:

Sustainable & ESG-Orientated Insights

Safety and sustainability go hand in hand. Read about our material choices, manufacture processes, and environmental impact:

Product & Specification Support

Need to move from insight to action? Here are tools and options to help specify the right equipment for your team:

Product Datasheets

Detailed specifications for Lyte product ranges:

Extension Ladders

GFNELT Glassfibre Extension Ladders

NELT Trade Professional Extension Ladders

Roof Ladders

Staging Boards

Towers & Podiums

Hilyte 500 Single Width Tower System

Hilyte 500 Double Width Tower System

StairLyte Industrial Tower System

Warehouse and Facilities

Multipurpose Ladders

GFLCL Glassfibre Combination Ladders

L3W Aluminium 3-way Combination Ladder

MagnaStep Step Ladders

Compliance FAQs

Short answers to common questions about ladder safety, standards, maintenance:

Regulations & Standards

What are my legal responsibilities under Work at Height Regulations (WAHR) 2005 regarding ladders?

Under WAHR, employers must avoid risk from working at height “so far as is reasonably practicable,” ensure equipment is safe, inspect before use, use alternatives (platforms, podiums, towers, etc.) where stepladders are not sufficient, and ensure users are competent.

What standards must portable ladders meet in the UK?

All new portable ladders must comply with EN 131 (parts covering stepladders, extension, combination) when manufactured and sold. Older standards such as BS 1129 and BS 2037 are withdrawn; ladders made to those may still be used if in good condition, but replacements must be EN 131 certified.

How do I know if a ladder is EN 131 “Professional” or “Non‑Professional,” and does load rating differ?

EN 131 categorises ladders into Professional vs Non‑Professional use. Both types now have the same load rating (typically 150 kg including user, tools, materials), but “Professional” ladders are built to withstand more rigorous use and tougher durability requirements.

What changes did the updated EN 131 standard introduce?

Key changes include stronger, wider stiles and rungs for better stability, same minimum load capacity (150 kg) across professional & non‑professional ladders, improved durability tests, all new ladders must meet EN 131; withdrawn old standards like BS 1129 & BS 2037.

What does PUWER mean for ladder inspection and maintenance?

PUWER (Provision and Use of Work Equipment Regulations 1998) requires that work equipment (including ladders) is maintained in a safe condition, inspected regularly, with records kept. Faulty ladders must be withdrawn from use.

What are the rules for ladders in electrical environments?

In environments with live electricity or potential contact, non‑conductive ladders (e.g. fibreglass / glassfibre or suitable timber) must be used. All users must assess risks, avoid contact with live components, maintain safe distances.

Are ladders banned legally?

No. Ladders are not banned. They are permitted under WAHR when risk assessment shows that using them is appropriate (low risk, short duration, existing features etc.). However, they should not be used where safer alternatives are reasonably practicable.

What is BS 8620, and when should podiums / podium steps comply with it?

BS 8620 is the standard for podium steps / low‑level work platforms, defining requirements such as guardrail height, gates, load, stability, platform dimensions etc. Any podium step purchased for workplace use should be BS 8620 compliant to meet legal and safety expectations. This standard replaced PAS250.

Ladders

Can I still use older ladders made to now‑withdrawn standards?

Yes — only if they are still in good condition, safely usable, regularly inspected, and used in accordance with manufacturer instructions. But for any new purchases or replacing worn ladders, only EN 131‐compliant ladders should be used.

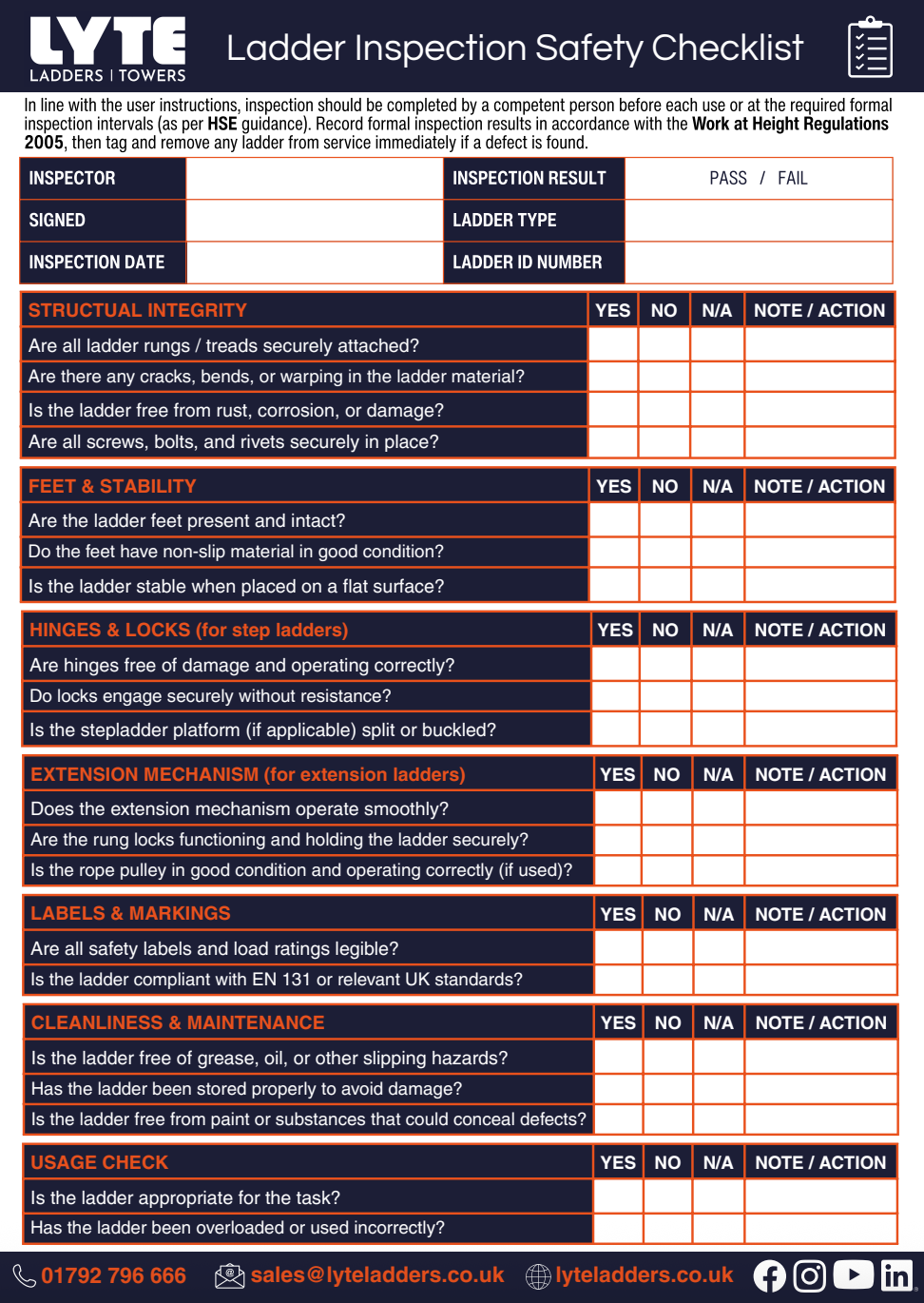

How often should ladder inspections be done?

Regular pre‑use / visual checks should be done every use or daily, looking for defects, damage, slipping, instability. More detailed inspections should be done at regular intervals depending on usage (weekly or monthly is commonly advised). Any failed ladder must be kept out of use.

Are there specific requirements for ladders used around electricity?

Yes. In electrical work (live or near live), use non‑conductive ladders such as those made from glassfibre(also known as fibreglass or GRP). EN 131 includes requirements for insulating properties in such ladders. Also, always assess electrical hazard risk around power sources.

How high is “too high” to use a ladder without switching to a safer platform or podium?

There’s no fixed height in WAHR when ladders become prohibited — the decision is based on risk assessment. However, if tasks are prolonged, involve reach, side‑on work, or risk of fall from height, safer alternatives (platforms, podiums, towers) are required. Many podium standards (BS 8620) come into play when guardrails become needed.

When is it acceptable to use a ladder versus when you should use a safer alternative (podiums, towers, scaffolding)?

A ladder may only be used if a risk assessment shows that using a higher level of fall protection is not practicable – for example, where tasks are short, low-risk and existing features can’t be altered; if the task is lengthy (e.g. more than ~30 minutes), involves frequent movement, or side‑on work or overhead hazards, safer equipment should be chosen.

What pre‑use checks / inspections are required?

Before every use, perform a visual / pre‑use check: examine stiles, feet, rungs/treads, locking mechanisms, ensure nothing has been dropped or damaged, check stability. In addition, formal inspections should be carried out at regular intervals (weekly or monthly depending on use) by a competent person, with records kept.

What does “competent person” mean in relation to ladder use and inspection?

A competent person is someone who has sufficient training, knowledge, practical experience and understanding of the relevant regulations, standards to be able to identify hazards, judge risk, inspect equipment safely, and know when to withdraw ladders from use.

Is there a limit on how long I can stay on a ladder?

The regulations themselves don’t set a strict time‑limit, but HSE guidance suggests that if work requires staying on a leaning ladder or stepladder for more than about 30 minutes continuously, then you should consider alternative access equipment. Also, prolonged tasks increase fatigue and risk.

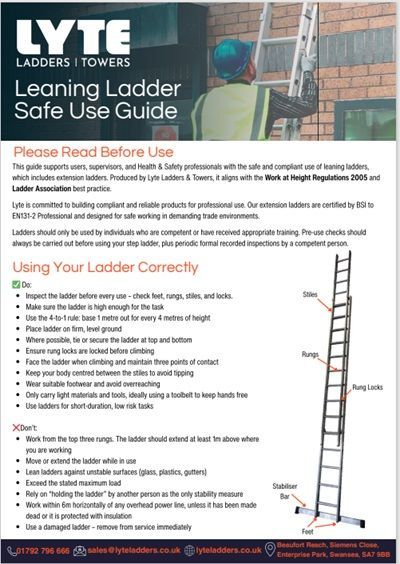

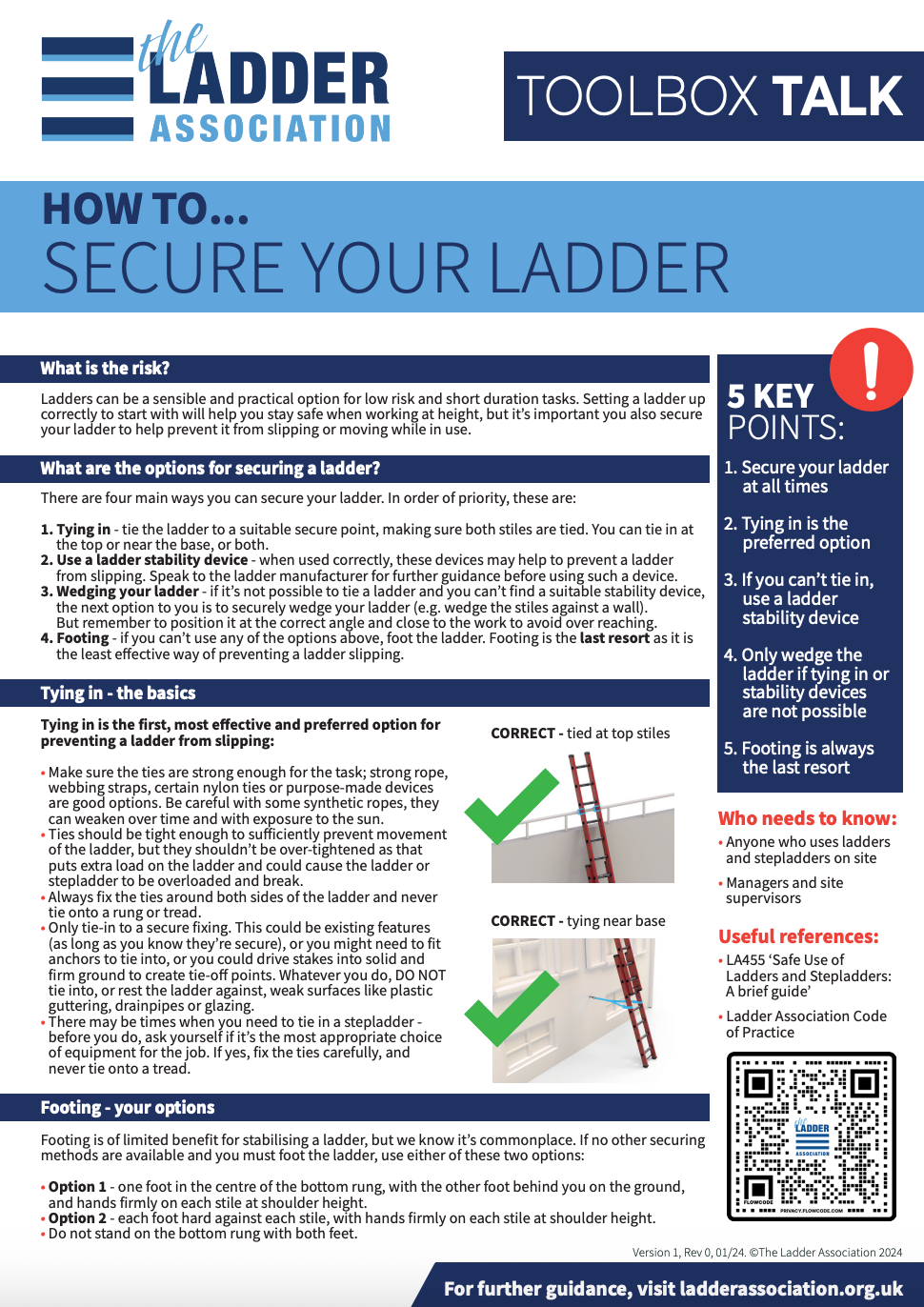

Should ladders be tied or secured, and how?

Yes. Ladders used for work should be prevented from slipping: tie both stiles to a secure point if practicable, or use ladder stability devices. Where tying isn't possible, footing (having someone hold the base) is a last resort. Also ensure base / stabiliser and top supports are secure.

What is the correct angle for a leaning ladder?

What is the correct angle for a leaning ladder?

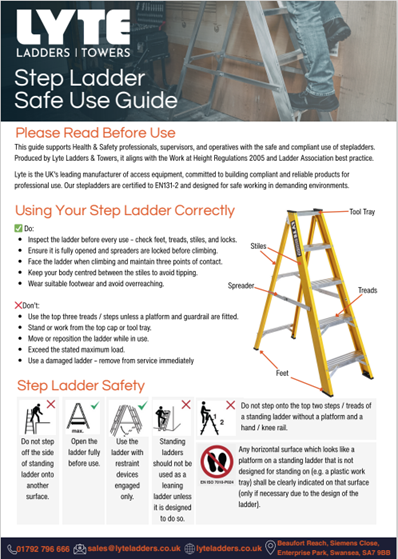

What are rules about standing height on stepladders?

Do not stand on the top three rungs of an extension ladder; Do not stand on the top three steps of a stepladder (including the top cap or tool tray) unless there is a suitable platform and handhold or kneerail. You must not work from the top-most steps without safeguards.

What if a ladder has defects — what constitutes withdrawal from use?

A ladder should be taken out of service (“withdrawn from use”) if defects are found such as cracks, splits, bent or damaged stiles or rungs, missing or damaged feet, faulty locking mechanisms etc. Inspection records should show defects and repair or replacement actions.

What training should users receive?

HSE advises users should be trained in ladder selection, safe setup (e.g. secure base, angle, stability), pre‑use checks, correct use (three points of contact, avoiding overreach, safe climb/descent), and when to use alternatives. Where tasks are more complex (frequent or high‑risk), more formal training may be required.

How should ladders be stored and transported to maintain safety and longevity?

Store ladders dry, protected from harsh weather and corrosive substances. Avoid damp or extreme heat. When transporting, secure ladders properly to avoid bending, dropping or other damage. Clean before use, remove mud, oil, chemicals.

Towers & Podiums

What is an EN 1004 tower, and how does the 2020 version differ from the old standard?

EN 1004‑1:2020 (published in the UK as BS EN 1004‑1:2020) is the current standard for mobile access towers. It replaced the previous EN 1004:2004 (BS EN 1004:2004) which was withdrawn in Nov 2021. Key changes include: covering towers of all heights (including below 2.5m), reduced distance between platform levels (max 2.25m), shorter distance from ground to first platform (max 3.4m), extra stability requirements (e.g. preventing castors falling out), and wind‑locking of platforms. These improve safety and limit fall risk.

Does every tower have to comply with EN 1004‑1:2020?

New towers bought or hired after the 2020 standard’s effective date should comply. Existing towers built under EN 1004:2004 can continue to be used if they are in good condition, certified, safe, and with correct instruction manuals. There was a transitional period from 2020‑2021 for switching to the new standard.

What does EN 1004:2020 require for platform spacing and first platform height?

Under the revised standard, the first platform (ground‑to‑platform) distance must not exceed 3.4 m, and the spacing between subsequent platform levels must not exceed 2.25 m. These changes help reduce potential fall heights when climbing or moving between levels.

What features must a compliant EN 1004 tower include?

Features include: purpose‑designed platforms with trapdoor access, guardrails on all open sides, sufficient stabilisers/out‑riggers (supplied with the tower, not “optional”), built‑in internal access (never climbing outside or using ladders leaning on the tower), correct instruction manuals, and components meeting the design loads. Towers should also have wind‑locking platforms (to prevent uplift), and must use approved safety methods (3T or AGR) when being assembled or dismantled.

What are the height limitations under EN 1004:2020?

For mobile access towers under EN 1004:1:2020, maximum platform heights are typically 8 m outdoors, 12 m indoors for standard mobile access towers. If the tower exceeds those heights, or if the configuration is non‑standard (multi‑bay, cantilever, etc.), it may fall under BS 1139‑6 instead.

When must towers be inspected, and by whom?

According to PASMA guidance, towers should be inspected: after assembly or any significant alteration, before use, after exposure to severe weather or any event likely to affect structural integrity, and at regular intervals (for example weekly for frequently used towers). Inspections must be done by a competent person. The inspection records should be maintained, often using a PASMA Tower Inspection Record.

Do I need PASMA training for using an EN 1004 tower?

Yes. Anyone who assembles, dismantles, moves, or inspects a mobile access tower should have completed the PASMA Towers for Users course. For supervisors / managers, additional or refresher training is advised. Even for relatively simple use, competency and having the instruction manual is required.

What about wind, unstable ground or external environmental risks?

Risk assessments must take into account weather (including wind), ground stability, and site conditions. Towers must be stabilised per instructions; loose boards, environmental loads (like wind) can overturn mobile towers. EN 1004 includes specifications for wind loads, stabilisers, and secure platforms. Towers should not be used when wind reaches certain thresholds, and no sheeting / netting that acts like a sail should be attached.

Can I use a tower to reach another place (transfer off the tower)?

Typically no. EN 1004 towers are not designed to be used to transfer to or from an adjacent structure. Transfer increases fall risk. If a tower is tied into a structure and special measures are met (sufficient ties, no gaps, risk assessment etc.), it still is a high‑risk scenario and must comply with all relevant regulations. PASMA’s guidance is clear that towers used as means of access are outside the intended use unless strict controls are applied.

What features should I look for in a safe podium step?

Key features include: guardrails on all open sides; self‑closing or inward‑opening gates; non‑slip platforms; stable base (locking castors or anti‑surf feet); load rating at least 150 kg; compliance with BS 8620. These features are designed to reduce risk of falls and misuse.

Industry Resources & Best Practice

Safety at height isn't just about the product, it's also about how you use it...

For personalised support, to request a product recommendation tailored to your working-at-height tasks, book a safety audit or ladder repair service, please fill in the contact form and a member of our team will be in touch.